The 5 essential questions to ask yourself to avoid making a mistake.

As with all your packaging, you need to ask yourself the right questions so that you can consciously choose between reducing your risks and optimizing your costs.

1 – WHAT IS THE PURPOSE OF A PALLET INSERT?

Product protection, pallet stabilization, communication support…

To find out more, see our article: Pallet insert plate: what’s it for?

2 – WHAT CONSTRAINTS NEED TO BE TAKEN INTO ACCOUNT WHEN CHOOSING A PALLET DIVIDER?

- Constraints linked to the nature of the products and their packagingForexample, liquid, powdery or pasty loads move during transport, making them more difficult to stabilize. Very light products are more difficult to stabilize than heavy ones, while small, heavy loads tend to shear the interlayer. Certain geometric shapes present a risk of perforation for neighboring batches: bottles, cartons, bags, cans, jerrycans, buckets, Big-bags, etc.

The type of pallet must be taken into account: a cardboard pallet will lack rigidity and will be flexible and unstable. A plastic pallet will be slippery, especially if the palletized products are also made of plastic. The base of a molded wood composite pallet will have asperities that are a potential source of instability. A one-way wooden pallet will have large gaps between each slat, potentially damaging your products.Wooden, composite, plastic, cardboard pallet…

- Logistics and transport constraints are your products placed on wooden pallets, plastic pallets or cardboard pallets?Are your pallets intended for travel or simply for internal storage handling?You’ll also need to analyze the route taken by the pallet: Does it undergo multiple loading and unloading? Are the pallets stacked during storage and/or transport?

What modes of transport will the pallet have to withstand: road, rail, sea, air, mail?

- Constraintslinked to your quality and environmental requirementsPalletsmust also meet your quality and hygiene standards: ISO 22000, HACCP. They must comply with specific regulations: FDA, CE 1935/2004, CE 2023/2006 and meet the environmental requirements deployed within your company: eco-design, FSC …

3 – WHICH MATERIAL, WEIGHT AND DIMENSIONS FOR PALLET DIVIDERS?

You have a wide choice of materials: paper interleaves , solid board sheets, single- or double-flute corrugated cardboard, honeycomb cardboard, plastic film, plastic interleaves, wooden sheets… And for each option, you’ll need to define the optimum grammage to avoid shearing and ensure the necessary rigidity of your pallet. Finally, should the pallet insert be the same size as, smaller than or larger than the surface area occupied by the products? For example, for a Europe pallet: 800X1200mm, choose a smaller format 780X1180mm, which will prevent the format from recessing the products for better presentation.

4 – WHERE SHOULD THE PALLET INSERT BE POSITIONED?

At the foot of the pallet (bottom), to protect products from the rising damp of the wooden pallet and its minor and major defects. Between layers, to stabilize the column or cross load and provide cohesion between layers. As a pallet cover, to protect against stacking and dust, or all 3!

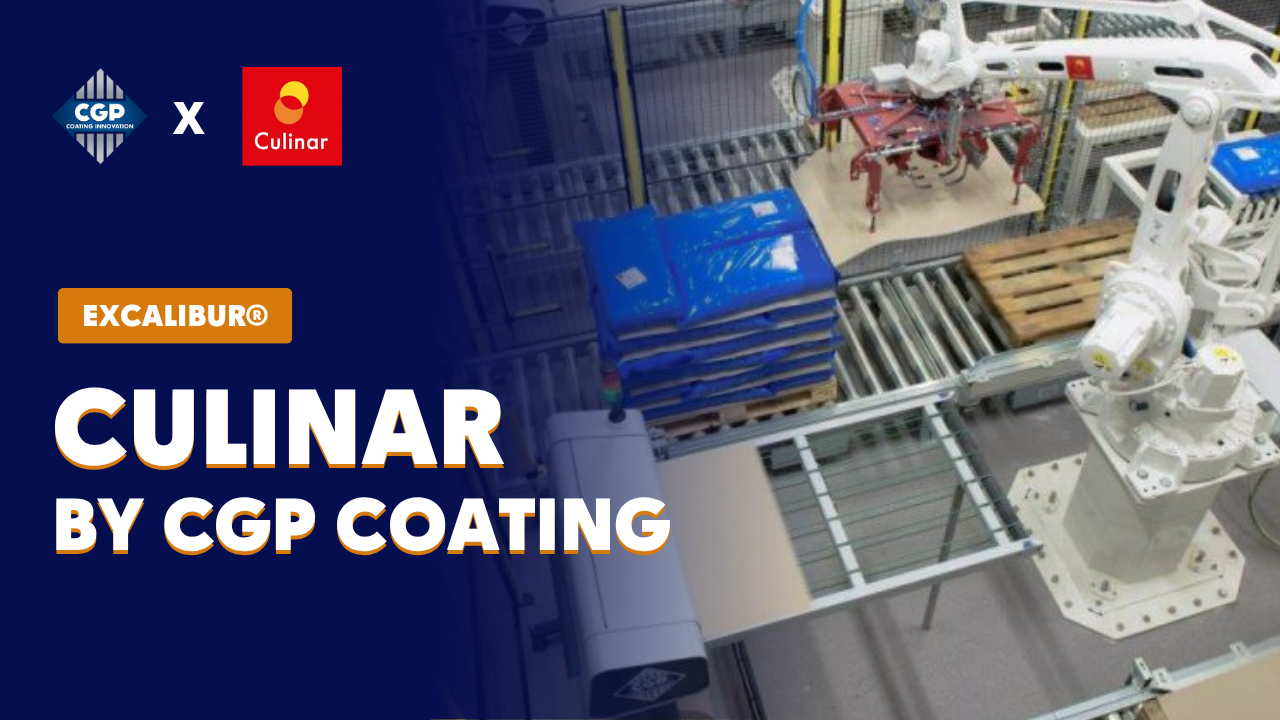

5 – HOW TO MAKE A SUCCESS OF YOUR AUTOMATIC PALLET INTERLAYER INSTALLATION PROJECT

First of all, you need to check that your palletizer is properly equipped to apply layer pads . You’ll also need to make sure that you have a warehouse and a gripping system capable of handling pallet dividers.

Do your teams know all the subtleties involved in optimizing automatic pallet layer placement? Do you have the internal resources to deal with these issues, or do you need expert advice in this field?