Concept

From a reel, it produces formats to the desired length. The formats are then automatically transported on a conveyor to a marked position. The gripper of the palletizer or palletizing robot picks up the format and inserts it between the layers of products to be palletized.

On demand, EXCALIBUR® rewinds the reel and cuts the next format. Its strength?

Your entire palletizing process is automated.

Our machine consists of:

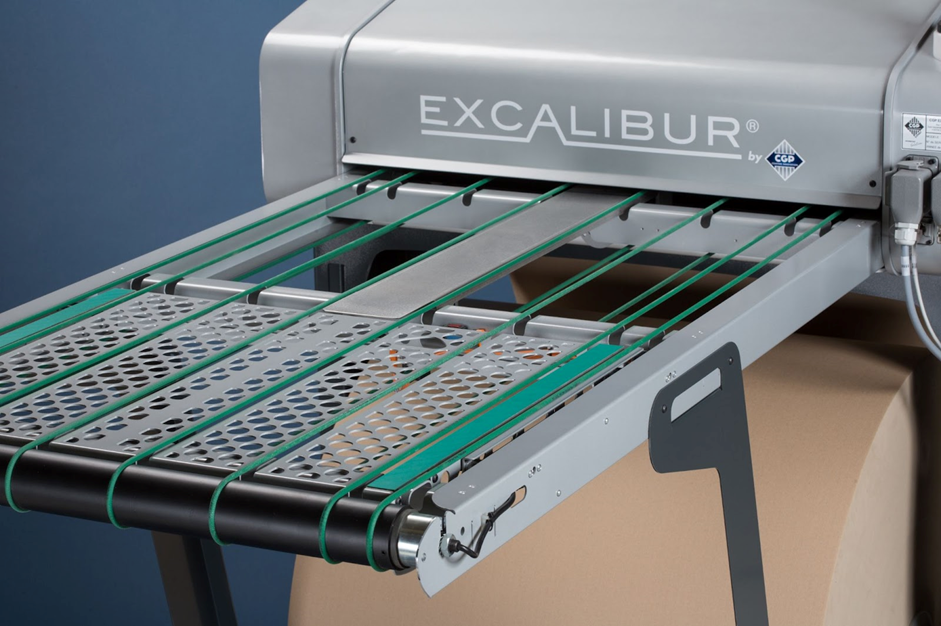

- A robust, reliable, and low maintenance cutting head. We have specially studied the cutting technology so that it is ideal for cutting paper;

- A positioning table so that the different formats can be adjusted to your palletizer but also so that they can be optimal to serve the gripping arm;

- An unwinder on a shaft or on a cart which allows the loading of the consumable outside the palletizer cell;

- And a simple HMI (Human Machine Interface) accessible by all operators.

Now that you’re familiar with how it works and its components, let’s take a look at our different types of machine models.

5 machine models to suit your needs

THE CONCEPT

Froma reel, it produces formats at desiredlength. The formats are then automatically transported on a conveyor to a marked position. T he gripper on the palletiser or on the robot on the palletiser retrievesthe format toinsert it between the layers of productsto be palletised . When required, EXCALIBUR® unwinds the reel again and cuts the next format.Its strong point? All your de palletisingprocessisautomated.

Our machine consists of :

- A cutting head that isrobust, reliable and requires very little maintenance.

- We have specially designed the cutting technology so that it is ideal for cutting paper;

- A de positioningtable so that the different formats fit your palletiser, but also so that they can be optimised to serve the gripper arm;

- A unwinder on axis or on trolley, which enables the consumables to be loaded outside the palletiser cell;

- And a HMI (Human Interface Machine) that is simple and accessible to all operators.

Now that you’re familiar with how it works and its components, let’s take a look at our different types of machine models.

5 MACHINE MODELS TO SUIT YOUR NEEDS

EXCALIBUR® BASIC model

It is an easy to use cutting model with “Plug&Play” technology.

Using a forklift or pallet truck, the operator brings the reel close to the machine and loads it onto the frame by rolling it. Then, they introduce the paper into the cutting head and program the desired cutting length on the HMI. The machine will then autonomously cut a format each time the absence of pallet interleaves has been detected on the conveyor table.

EXCALIBUR® CLASSIC model

It is a model to be integrated in your palletizer, with a high degree of efficiency.

Using a forklift or pallet truck, the operator loads the reel onto a dedicated reel stand cart (the operation can be carried out in the raw material warehouse). Then they bring the wheeled cart and set it up at the foot of the cutter.

After having introduced the paper in the cutting head, they can either program the desired cutting length on the HMI so that the machine cuts the formats in autonomous mode, or let the line control the tool and order the reference to be produced.

Consumables are loaded via a wheeled cart which facilitates the approach of the consumable within the production workshop.

It is capable of cutting UNO multi-size formats, DUO half-pallet formats, as well as QUATTRO quarter-pallet formats.

EXCALIBUR® EXTENDED model

This is a model with a spacer positioning plate that adjusts to the constraints of the gripper arm. The formats are fed into the palletizer at a given point, always at the same level.

It can be integrated on all types of automatic palletizing lines: polyarticulated robotic palletizers, high-level palletizers, low-level palletizers, bag palletizers, box palletizers, etc.

EXCALIBUR® GIRAFFE model

This is a model dedicated to top layer palletizers (high-level).

The unwinder and the consumable reel remain on the floor, as well as the connection station and the HMI controls. The machine offers access that facilitates and secures the work of the operators.

The cutting head and the format positioning plate are positioned high up near the product layer composition platform. The format is delivered as close as possible to the gripper which will pick up and place the format on the pallet.

The machine is equipped with a connecting table, thus avoiding the operators moving back and forth between the floor and the palletizer platform during the reel change operations.

EXCALIBUR® BASE DISPENSER model

It is a compact model dedicated to the cutting of pallet base formats. The compact machine is positioned near the pallet magazine. Reels are loaded via a cart with wheels or directly on the machine frame. Once the cut is made, the format is available on the placement tray. A Cartesian gripper arm integrated into the machine picks up the sheet and places it on the pallet.Although some models are perfectly suited to be installed in most palletizing lines. With our solutions, you will have a tremendous amount of flexibility for carrying out your projects.

Tailor-made solutions for managing palletizing inserts

As you can see, EXCALIBUR® is a modular machine. If the configuration of your line requires an adaptation to implement our format cutting machines, including for example modifying the reel management, modifying the sheet passage, or operator access to the cutter, contact on our research and engineering department to create your custom solution.

Our solutions allow you to bring more safety to palletizing lines.

The “IN/OUT” set-up, the HMI, and the reel are accessible to the operator without having to enter the palletizing cell, which allows you to reduce the risk of accidents.

It’s not a problem if you can’t opt for this setup. In this case, you should use a safety fence attached directly to the EXCALIBUR® base. This eliminates the risks associated with handling the machine.

Our design office masters the design (project studies, overall plans, mechanical studies, and detail plans), the assembly, the installation of the machines, and the training of the production and maintenance teams.

For a pre-study to evaluate the technical feasibility of your integration project, contact our CGP Coating Innovation experts.

Tremendous flexibility for financing your project

The various possibilities of acquiring EXCALIBUR® will allow you to benefit from a solution adapted to meet your needs both from an ergonomic and economic point of view.

Our machine is available for purchase or as a zero investment package. This formula is subject to rental or to the provision of our customers without contribution in case of signing a contract of consumable supply.

EXCALIBUR®, an ideal tool for reducing your palletizing costs.

Our palletizing solutions allow you to reduce the weight of your interleaves: you replace your corrugated cardboard sheets with paper dividers of lower grammage.

It also allows you to reduce the number of references to be supplied and the elimination of the changes of your consumables related to the changes of formats. You can even cut several sizes from one coil size.

Moreover, with EXCALIBUR®, you have a great deal of flexibility in your production management because it works in autonomous or controlled mode with up to 15 references. This system eliminates the need for frequent operator intervention to feed the format magazine, allowing you to focus your workforce on productive activities.

When it comes to managing consumables, you also reduce your stocks since you use less: 1 reel of paper replaces up to 5 pallets of corrugated cardboard!

From an ergonomic point of view, the loads are no longer carried manually and changing consumables is carried out in complete safety thanks to the use of a wheeled cart. There is therefore also an improvement in working conditions for the operators.

For high-level palletizers, the consumable remains on the floor, but the paper reel is also loaded safely outside the palletizer cell.

Quality of life at work is therefore better thanks to our different and modular machines.

If after this detailed explanation you would like to know more, download our product sheets.