Our Products

Logistics packaging

Anti-slip pallet interlayers

Automatic Palletising

Elastic Pallet Bands

Load Securing and Load Unit

Slip-sheet pallet less handling

Protective packaging

Transition Packaging from Plastic to Paper

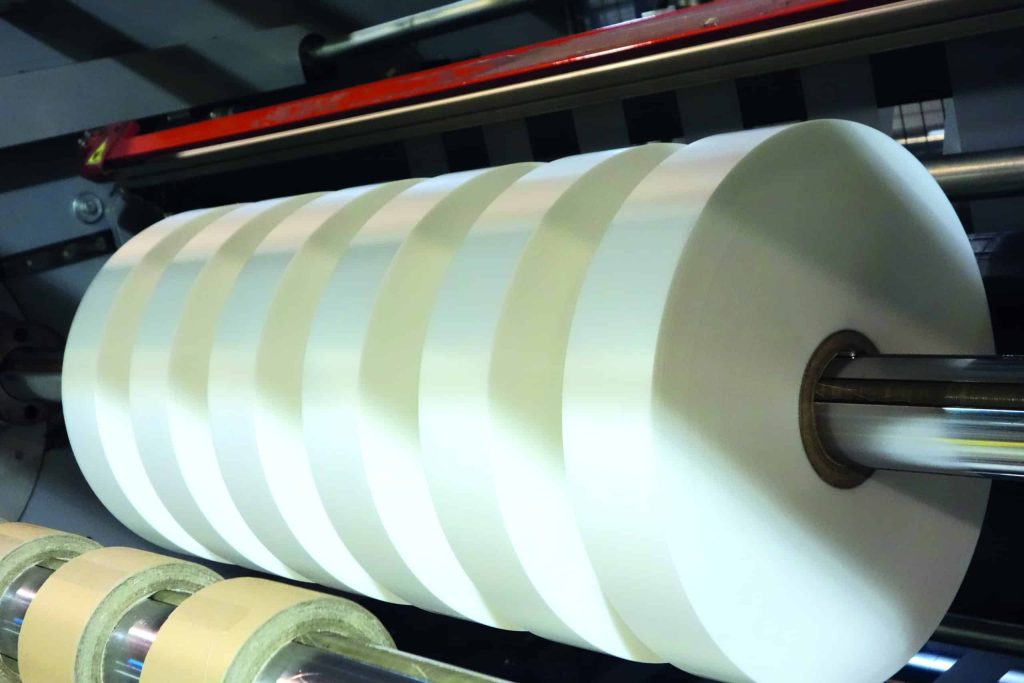

Paper Rolls & Sheets for Sustainable Packaging

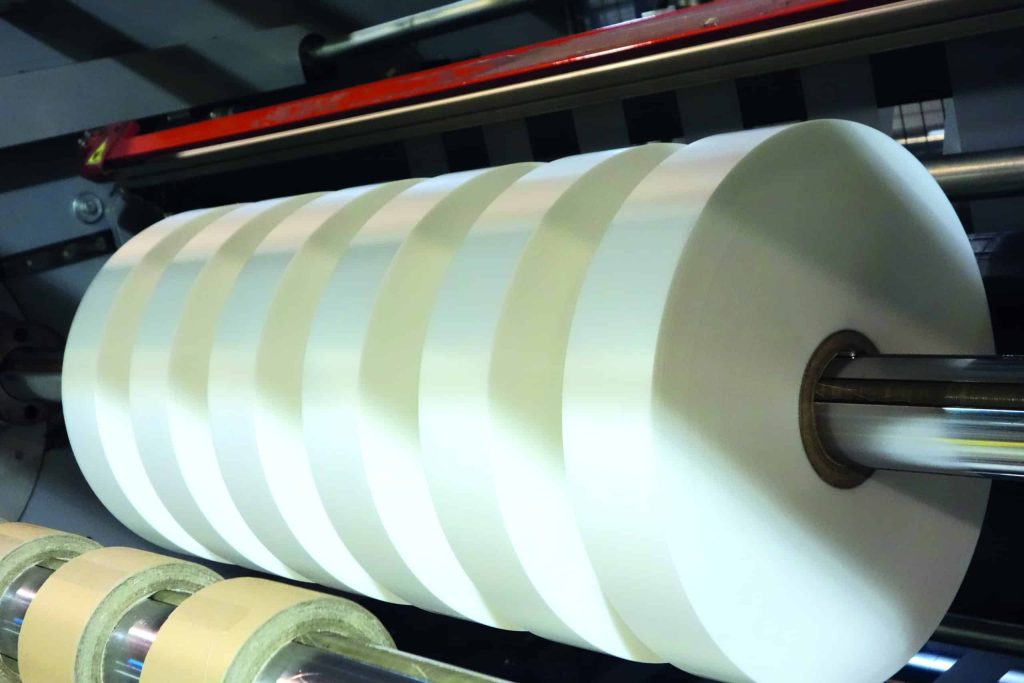

Custom Plastic Packaging Films

CGP BERRY – Cartonnage

Specialist in the manufacturing and processing of technical cardboard packaging

Equipped with a modern and diverse fleet of machines, CGP BERRY offers a wide range of products, from corrugated to solid board, including creative papers and innovative solutions for point-of-sale advertising (POS).

About us

About CGP

Group

Professions – Manufacturer

Team

Resources

Blog

Our news

Testimonials

Documentations

Documentations

Access all our resources: Product sheets, case studies, white papers, and more.

- Home

- Our Products

Specialist in the manufacturing and processing of technical cardboard packaging

Equipped with a modern and diverse fleet of machines, CGP BERRY offers a wide range of products, from corrugated to solid board, including creative papers and innovative solutions for point-of-sale advertising (POS).

Impression 8 couleurs Haute Définition disponible sur toute notre gamme.

Our news

Explore our blog dedicated to our solutions, featuring insights into our technical innovations, expert analyses, practical advice, news, and feedback to support you in your projects.

- Resources

Our news

Documentations

Access all our resources: Product sheets, case studies, white papers, and more.

- About us

A group firmly focused on its clients and international development

CGP COATING INNOVATION, the world leader in anti-slip coatings, and a specialist in packaging and process solutions.

About

Professions – Manufacturer

Group

TEAM

Latest news

- Home

- Our Products

Specialist in the manufacturing and processing of technical cardboard packaging

Equipped with a modern and diverse fleet of machines, CGP BERRY offers a wide range of products, from corrugated to solid board, including creative papers and innovative solutions for point-of-sale advertising (POS).

Impression 8 couleurs Haute Définition disponible sur toute notre gamme.

Our news

Explore our blog dedicated to our solutions, featuring insights into our technical innovations, expert analyses, practical advice, news, and feedback to support you in your projects.

- Resources

Our news

Documentations

Access all our resources: Product sheets, case studies, white papers, and more.

- About us

A group firmly focused on its clients and international development

CGP COATING INNOVATION, the world leader in anti-slip coatings, and a specialist in packaging and process solutions.

About

Professions – Manufacturer

Group

TEAM

Latest news